As reported by the Straits Times, Singapore officially launched its very first eco-solution manufacturing plant last May 2022. While this endeavor reflects the urgency to explore sustainable manufacturing in Singapore, it is also indicative of a growing trend wherein businesses hope to incorporate environmentally friendly processes in their operations.

Eco-Solutions Manufacturing

Officially entitled the Green Lab, the facility aims to provide businesses with sustainable packaging solutions, such as biodegradable paper bags and compostable packaging – which is especially relevant for those operating in the food and beverage sector.

From an environmental and business perspective, this facility is markedly different from other manufacturing plants as it places an emphasis on sustainability throughout its operations. It offers eco-friendly business solutions such as compostable bags that are crafted from the recycled waste of cassava roots. Other notable solutions include packaging peripherals (banners, stickers, etc.) that are produced without the use of traditional chemicals, namely, polyvinyl chloride or PVC.

Although these solutions are only currently produced by the Green Lab, it is important to note that future manufacturing plants will likely consider integrating sustainable practices in their operations as stakeholders are becoming increasingly receptive to such developments.

Potential investors should also recognize that the emergence of these solutions is indicative of a trend wherein businesses are proactively exploring opportunities that have a sustainable and environmentally friendly focus. Given that Singapore is keen on achieving the goals set forth in the Singapore Green Plan 2030 as guided by the UN’s Sustainable Development Agenda, these opportunities manifest well beyond that of the manufacturing industry, specifically in sectors like construction, real estate development, retail, etc.

Exploring Future Opportunities

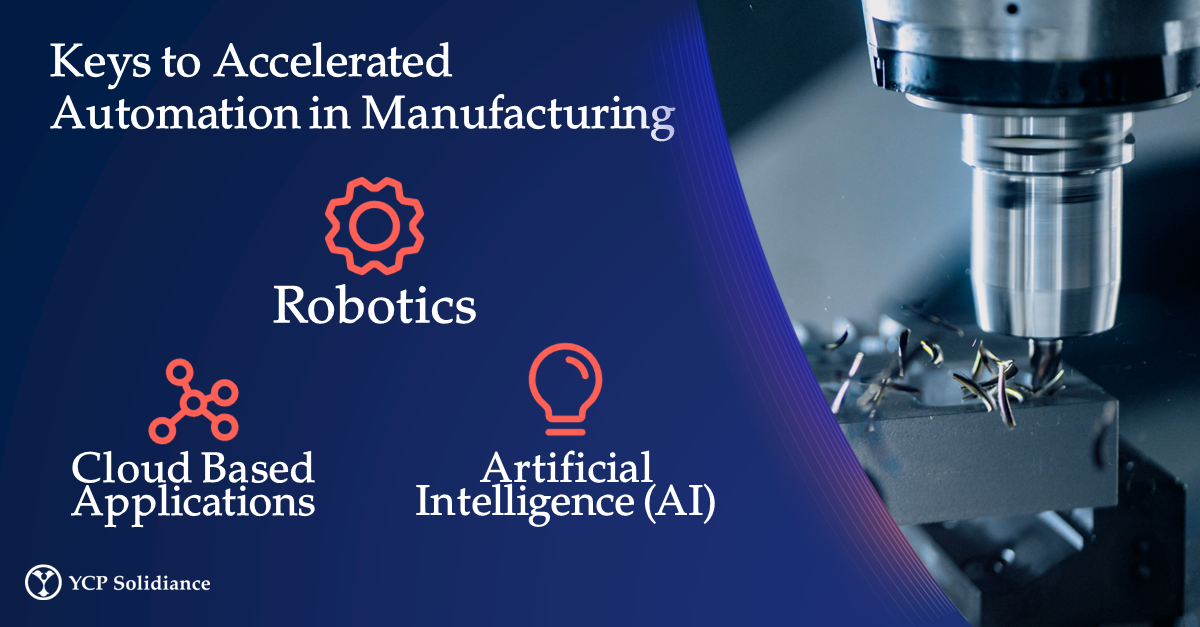

In the context of manufacturing, sustainability and eco-friendly solutions are often seen as a more expensive option that can discourage potential investors. Thus, the application of automation will help ensure that sustainable business solutions become cost-friendly options. In the YCP Solidiance white paper “Road to Recovery: Post Pandemic Business Outlook in Southeast Asia,” several strategies to accelerate automation were discussed, as informed by the ASEAN Consolidated Strategy for the fourth industrial revolution.

For instance, cloud-based applications could be applied to help accelerate automation in manufacturing as it helps store and centralize information through data centers, which seeks to improve operational efficiency as data becomes readily accessible to users. Another strategy that may be applied is robotics, wherein quality and overall productivity at a lower cost become the focal point via decreased reliance on manpower.

Furthermore, supply chain resiliency as characterized by flexibility and interchangeability of procurement—be it in regard to suppliers or components—should also be a significant consideration for those in the manufacturing industry. In his panel on automation for the aforementioned YCP Solidiance report, Kiat Hui Tan of Emerson Automation Solutions shares what he believes is perhaps the most critical part of establishing supply chain resiliency in a post-pandemic world: “The truth of the matter is that especially for more complex manufacturing industries, the switching cost is very high. You have to make sure that you do your risk assessment correctly in sourcing your most critical parts from a resilient country.”

Overall, the exploration of sustainability and environmentally friendly practices in manufacturing processes will prove to be a fruitful venture as it bleeds into other related industries. As such, there are endless opportunities for investment and potential business growth. In the coming years, expect more and more businesses to establish sustainability as a major priority.

To get insight on other business trends in Asia and how businesses are adapting accordingly, subscribe to our newsletter here and check out these reports: