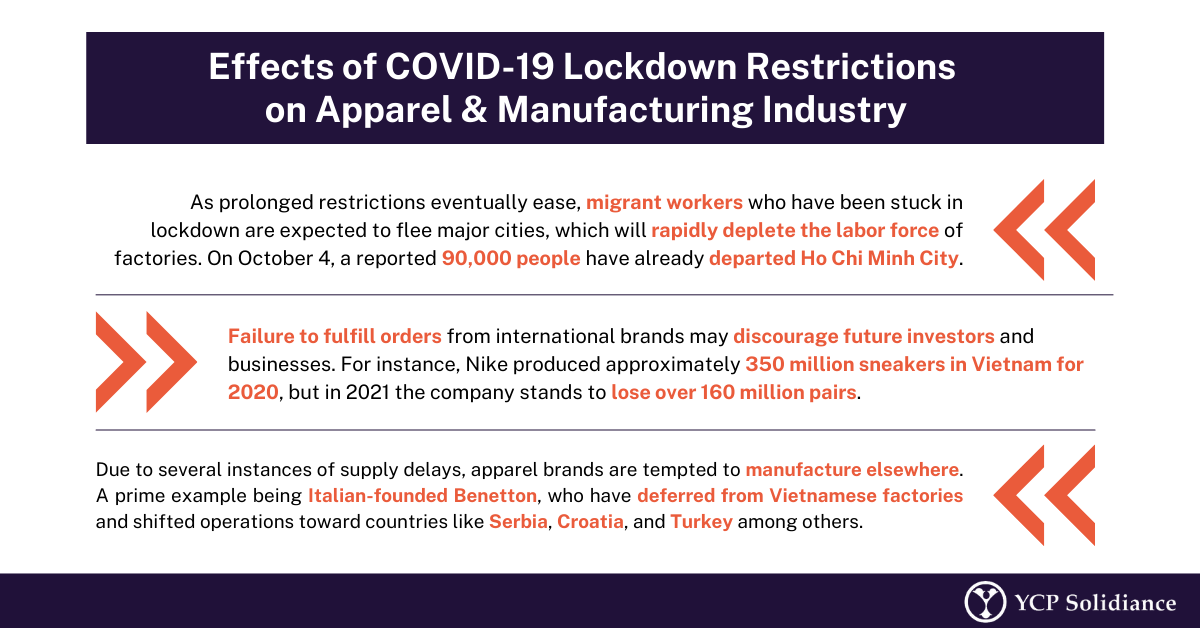

Due to strict and prolonged COVID-19 lockdown measures imposed in Vietnam, the country’s apparel manufacturing industry is under threat of losing its status as a manufacturing powerhouse for international apparel brands. Restrictions in place have limited the operational efficiency of factories, and global brands like Nike and Gap are set to experience product shortages—a concerning development, especially when considering the potential economic implications involving such a disruption.

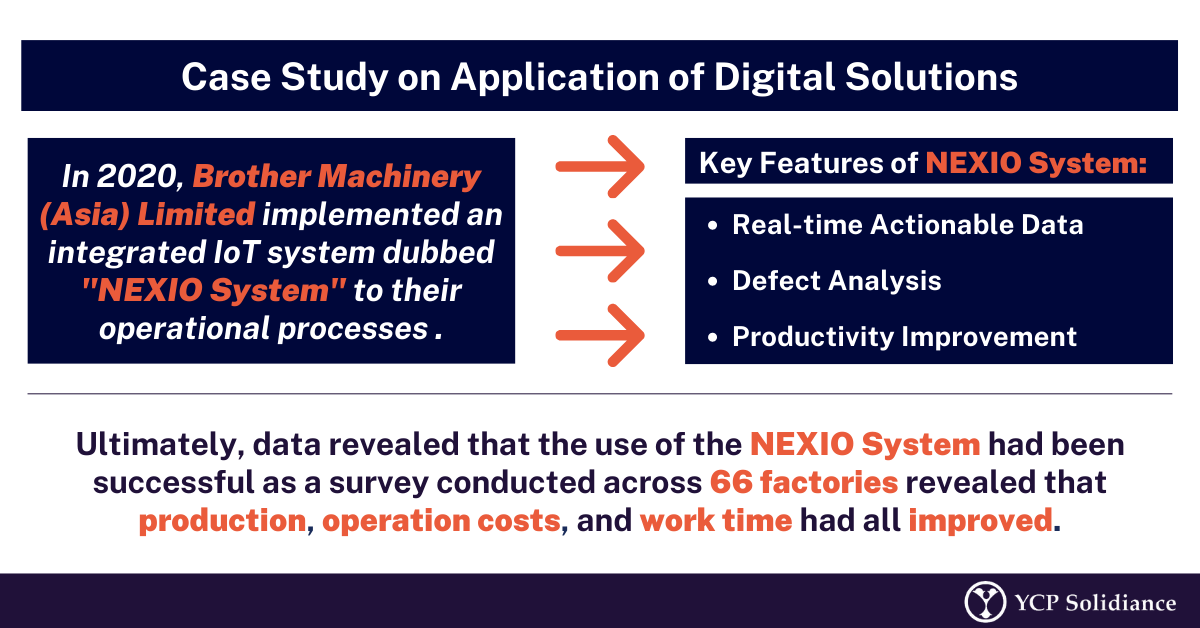

However, much like how other sectors have weathered the effects of the COVID-19 pandemic, accelerating the digital transformation of the apparel manufacturing industry is shaping up to be the answer to many of the industry’s problems.

The Issues Faced by Vietnam’s Apparel Manufacturers

As per an article by Japan Today, the Hung Yen Knitting & Dyeing fabric mill located to the east of Hanoi—a factory responsible for production and supply to several international clothing brands—reported that their manufacturing output plunged by 50%. The same report states that due to the lack of mobility caused by travel restrictions, Vietnamese factories are also experiencing logistical delays as failure to deliver manufacturing necessities is becoming a frequent occurrence.

Digitally Transforming the Apparel Industry

Although present efforts to contain COVID-19 in Vietnam are currently underway, the proponents involved in the manufacturing of apparel can do little but wait and plan for future endeavors. With that, Vietnam and its domestic factories should consider the importance of ensuring the digital transformation of manufacturing chain processes, specifically in the apparel industry.

For example, one of the largest fabrics producers in the Nam Dinh province, Bao Minh Textile JSC, was able to apply several digital solutions and successfully automate its processes. By doing so, the fabric producer was able to reduce the number of direct workers as well as gather relevant manufacturing data through production equipment.

In line with improving manufacturing processes in the apparel industry through digital means, the Vietnamese government has developed a country-wide digital transformation project called the National Digital Transformation Programme. Among the initiative’s goals is for the nation’s digital economy to experience a growth of 29% by 2025, and to do so, a large focus will be dedicated to accelerating digital transformation in eight specific sectors, with manufacturing as one of them.

As both the government and private companies involved in apparel and manufacturing position themselves to digitally transform in a post-pandemic era, the road to recovery will surely be less turbulent.

For more insight on the development of manufacturing and apparel industries within Asia, subscribe to our newsletter here.