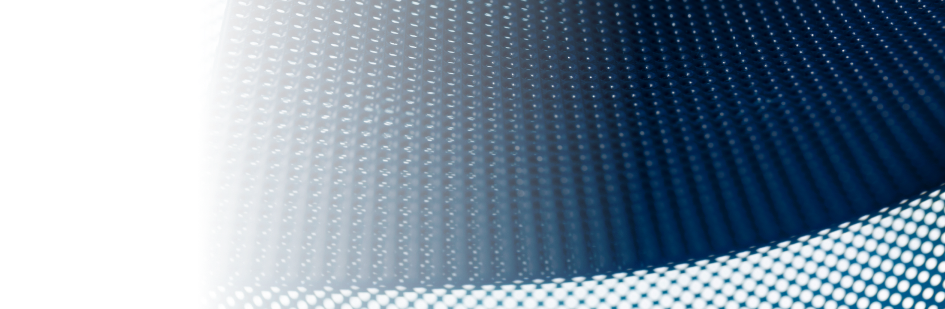

On a yearly average, a single passenger vehicle can typically emit 4.6 metric tons of carbon dioxide due to several factors, such as fuel consumption and vehicle usage. Moreover, according to research from the World Economic Forum, the automotive industry, as of 2021, now produces more greenhouse gas emissions (with approximately 20% coming from manufacturing) than the entirety of the European Union.

With this, electronic vehicles (EVs) have become a priority for the automotive industry, especially in Asia wherein automotive manufacturers play a major role in attempting to reduce pollution in major cities. While the use of EVs do lessen greenhouse gas emissions, the carbon footprint created by the EV manufacturing process is a concern as it leads to more carbon emissions than the production of a regular petrol vehicle, as per an article by CNBC.

Electric Vehicle Batteries

In the context of the EV manufacturing process, the recyclability of electronic batteries is perhaps the foremost priority. Generally, EV batteries have a life expectancy of approximately 8 to 15 years. If the automotive industry can salvage and recycle these batteries past their initial shelf life, the impact that it could have on reducing carbon emissions may be groundbreaking on many levels.

Not only would recycling EV batteries help consumers in maintaining and prolonging the usability of their vehicles, but more importantly, demand for resources such as lithium, nickel, and cobalt would drastically lessen, as per data from a report by the Institute for Sustainable Futures.

International Movement

Organized support for the initiative to establish a sustainable EV manufacturing process is already in the works, as evidenced by the progress made during 26th UN Climate Change Conference of the Parties (COP26). Governments, businesses, and private organizations alike expressed a commitment to sustainably develop the future of the automotive industry.

While the project—formally titled the “COP26 Declaration on Accelerating the Transition to 100% Zero Emission Cars and Vans”—focuses primarily on achieving 100% zero emission sales of new vehicles and vans by 2024, the agreement is still significant as it can help set the foundation for EVs to succeed globally. Despite emissions from major countries like the United States and China, as well as automobile brands such as Toyota and Volkswagen, still being significantly high, the initiative is nevertheless a step in the right direction for sustainability within the automotive industry.

Leading By Example

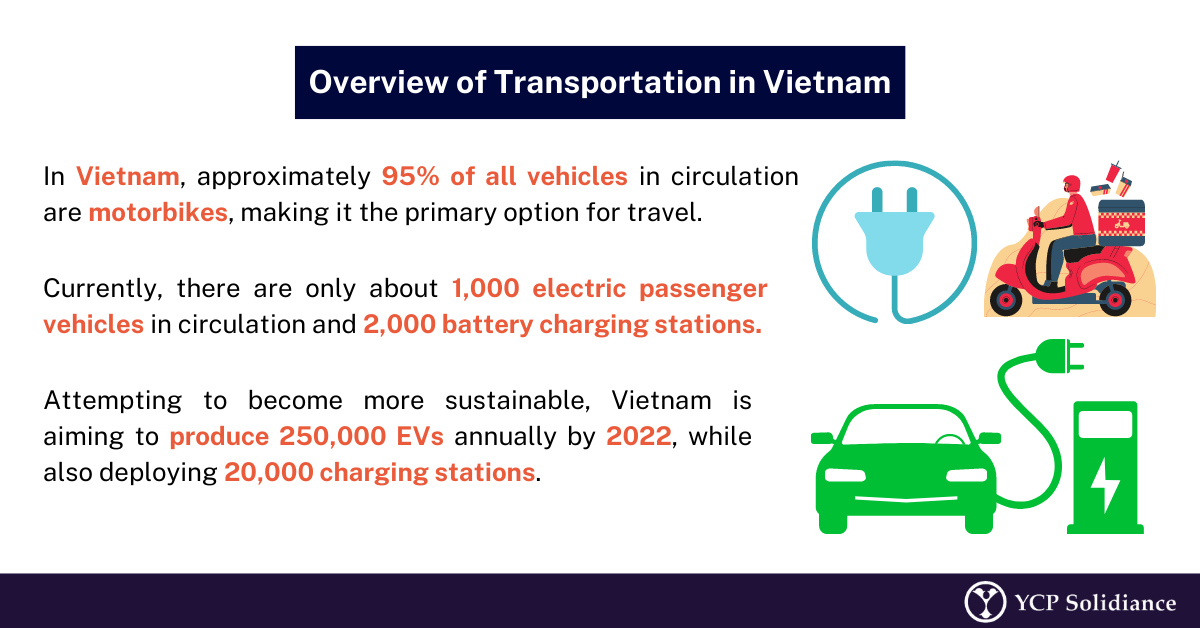

In the YCP Solidiance white paper Public and Private Sector Cooperation: Sustainable Urban Development in Vietnam, the green revolution in Vietnam and its transition toward developing sustainable cities is explored. As part of the Program for National Digital Transformation for 2025-2030, sustainable transportation has been recognized as a point of emphasis for further development.

Furthermore, in the YCP Solidiance white paper The Future of Mobility in China: Internet of Vehicles, research shows that China’s new energy vehicle segment is also experiencing significant growth. As a result of several initiatives such as the Corporate Average Fuel Consumption (CAFC), NEV Credit Regulation, and a government-backed, five-year plan to emphasized strategic development of the new energy sector, the annual sales volume of clean energy vehicles in 2018 increased by 62%.

Through the continued efforts of international organizations, governments, and other involved stakeholders, the automotive industry is fully capable of establishing sustainable processes in manufacturing and production. The shift to adopting environmentally friendly practices (like the use of EVs and recycled batteries) cells will be gradual, but the steps taken will be essential to creating societies that are sustainably sound.

For more insight into the automotive industry’s mission to becoming sustainable in its manufacturing processes, subscribe to our newsletter here.