Given that Artificial Intelligence (AI) has played a pivotal role within industries that operate in digital spaces like tech and finance, trends suggest that the same benefit can be extended to other industries and their processes. Specifically, technological solutions centered around AI may help address long-standing issues in areas such as construction, manufacturing, and building maintenance. In the context of logistical operations, AI technology will be advantageous in intralogistics, trunk line logistics (B2B), and the last mile (corporate-individual)—something that is already being explored in Japan’s logistics industry.

To understand how Japan’s logistics industry can leverage the implementation of AI technology, read this excerpt from our white paper The Future of Technology in Social Infrastructure, an English translation of our original Japanese publication, which can be read in full here.

Since the 2010s, the use of AI technology for large-scale data has been greatly promoted in the web domain, including with Google, Apple, Facebook, and Amazon (collectively known as GAFA), and in the financial domain that includes trading operations at securities companies and credit evaluation and risk management in banks. These industries are characterized by the fact that they have already accumulated a vast amount of digital data and have established standardized operations using IT systems.

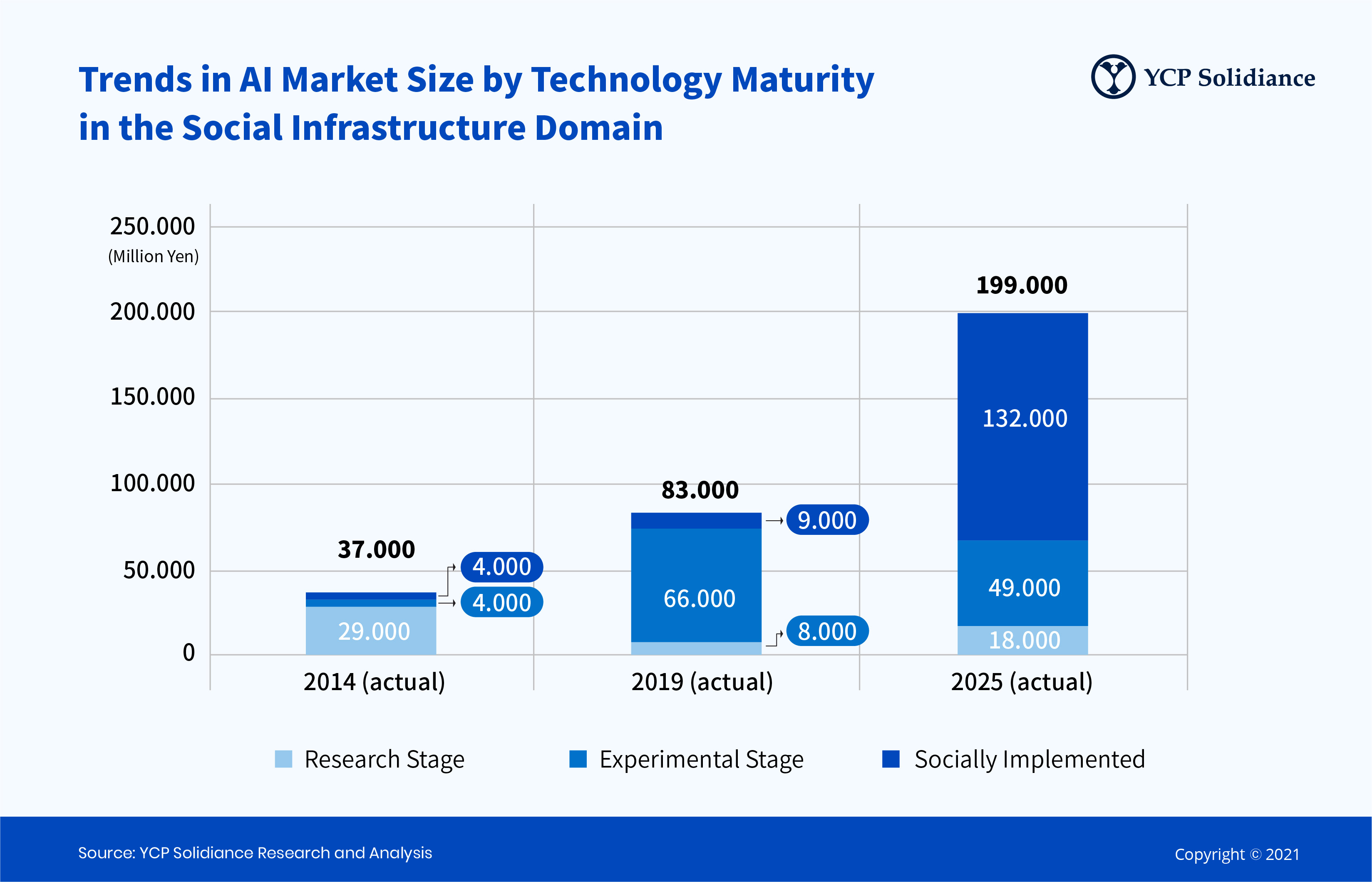

AI technology, which has been developed mainly in the aforementioned areas of digital space such as the Web and in finance, will be transferred to more “physical” areas such as manufacturing, distribution, and energy in the future. Currently, most of the applications of AI technology in social infrastructure are in the R&D and technology verification stages. However, as social issues such as the aging of public infrastructure and the decline of the working population become more serious, the social implementation of AI is expected to progress steadily.

Conditions to Reach Social Implementation of AI

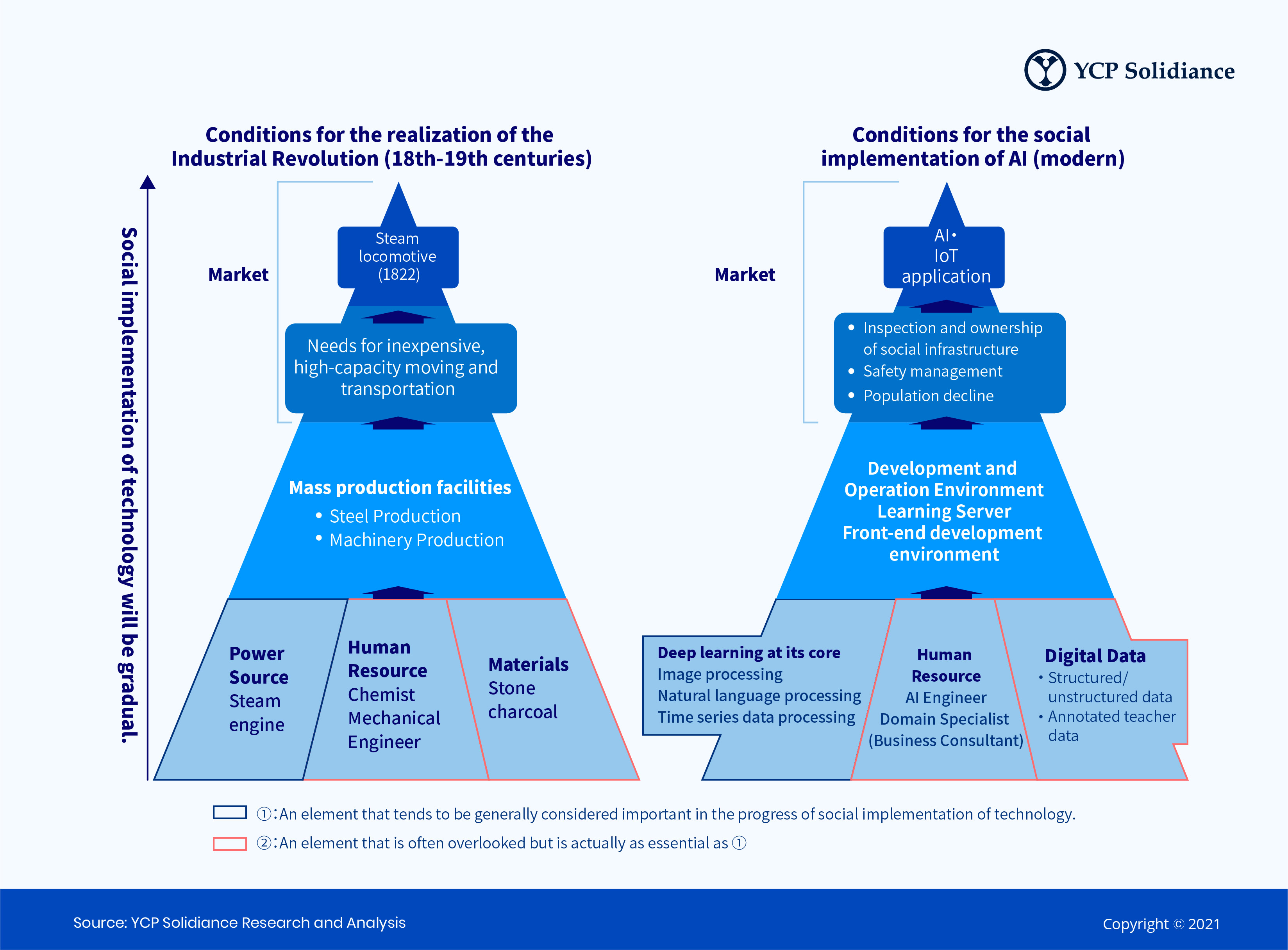

In order to utilize AI in the physical domain, it is important to create a foundation for the accumulation of data and standardization of operations, so it is expected to take several years from the start of consideration to implementation. Looking back on history, it took many years for the steam locomotive—that has now become a synonym for the Industrial Revolution—to be implemented in society (it took 100 years from the development of Newcomen’s steam engine to the practical application of Stevenson’s steam locomotive), and it is believed that the social implementation of AI will proceed in a similarly gradual manner. Just as chemists and mechanical engineers worked together to contribute to innovation during the Industrial Revolution, business consultants and AI engineers will work together to reform business operations in the future.

The social implementation of AI is expected to progress gradually through the maturation of technologies and markets, similar to the steam engine technology during the Industrial Revolution. In the process of social implementation, the key is not only AI algorithms, but also the availability of human resources and digital data to promote social implementation.

In recent years, the increasing demand for transportation due to the expansion of the e-commerce market, combined with the shortage of manpower in the logistics field, has increased the workload of the logistics industry to the extent that it has been called a “logistics crisis.” In 2017, a similar situation called the “courier crisis” arose as a symbol of this “logistics crisis.” In addition, manufacturers, who consider logistics as a lifeline for their business, are also facing issues such as increased transportation lead times and soaring costs due to the logistics crisis and are required to re-examine their logistics strategies.

In recent years, the introduction of AI, Internet of Things (IoT), and other technology has been attracting attention as a solution to these emerging issues. In this chapter, we will examine the issues surrounding logistics, clarify the factors behind these issues, and analyze how companies in the logistics industry should utilize technology in the future.

Challenges in the Logistics Field and Tech Solutions

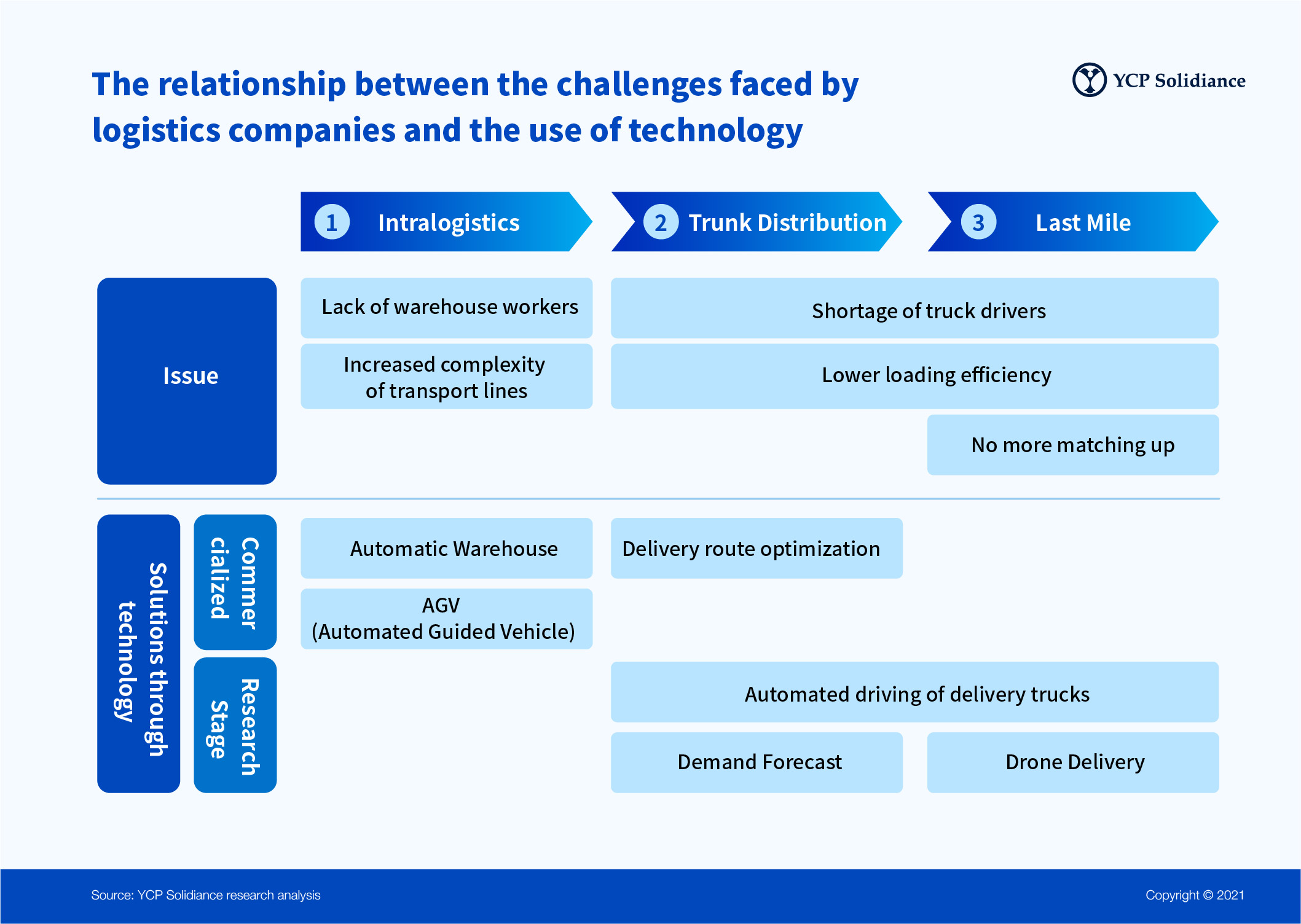

In what has been called the “logistics crisis,” companies that make their living in logistics are facing a variety of challenges in warehouse logistics, trunk line logistics, and the last mile. As labor shortages worsen, labor-intensive solutions to these challenges are reaching their limits, and efforts to utilize technologies such as AI and IoT have begun. The relationship between the overall issues and the use of technology, including those still in the research stage, can be summarized as follows:

Issues:

- Lack of Warehouse Workers – Although the labor shortage for warehouse workers has been as drastic as that of truck drivers, labor costs for warehouse workers are also on the rise (the nationally weighted average of the revised minimum wage by region in FY2017 was 848 yen, an increase of 25 yen). While truck freight rates are on an upward trend due to the shortage of drivers, warehouses have not made much progress in passing on the higher labor costs to prices, which is a factor pushing down the profit margin for warehouse operators.

- Increased Complexity of Transport Lines – With the expansion of the EC market, high-mix, low-volume production is progressing.

Solutions Through Technology:

- Automated Warehouses – Automated warehouses are warehouses that have a system that centrally manages the entire process of warehousing products, from receiving and storing, to shipping, which makes it possible to reduce the number of manhours required for warehouse operations.

- AGV (Automated Guided Vehicle) – AGV is an acronym for Automatic Guided Vehicle, which refers to a vehicle that transports products and parts unmanned within a factory or warehouse. In recent years, the use of AI and IoT within this area has increased, leading to the remarkable growth and evolution of AGV development. Through image recognition and machine learning, AGVs can run autonomously on irregular routes and analyze and optimize travel routes, and are becoming an effective solution to increasingly complex transportation lines.

Trunk Line Logistics (B2B)

Issues:

- Shortage of Truck Drivers – While the volume of cargo is increasing, the unpopularity of the industry continues due aforementioned factors (declining birth rate, aging population, and the image of a harsh working environment), making the driver shortage even more serious. The Ministry of Health, Labor and Welfare (MHLW) has set the working hours for truck drivers at up to 13 hours per day on principle, with the possibility of extending this to 16 hours depending on the situation. They are also allowed to work no more than two 15-hour days per week, which is overwhelmingly longer than the eight-hour working hours set by most companies. In addition to this, in recent years, there has been an increase in the number of cases where sellers claim to offer “free shipping,” and it is thought that this wrinkle in improving services for consumers has also had an impact on the decline in wages for drivers. In addition, the more complex the conditions are in terms of traffic conditions and time required for delivery, the more experience and expertise is required for the task of creating delivery plans, which is essential in this line of work. Knowledge of such routes is subjective, and if only a specific person can create the delivery plan, there is a risk that it will be difficult to continue the work due to the retirement or absence of the person concerned.

- Lower Loading Efficiency – Loading efficiency refers to the ratio of the weight of cargo actually loaded to the maximum loading weight of a truck. As transportation becomes more frequent among a smaller pool of workers, the loading efficiency of commercial trucks continues to decline year by year, and as of 2018, it has dropped from 55% in the 1990s to about 40%. With the increasing shortage of truck drivers, improving the efficiency of delivery, including loading efficiency, is an urgent task.

Solutions Through Technology:

- Optimization of Delivery Routes – A system that supports the creation of delivery plans to optimize the loading of trucks and driving routes when transporting goods can reduce the delivery time of drivers and the work of creating new routes.

- Automated Driving of Delivery Trucks – As a solution to the shortage of truck drivers, research and demonstration tests for the practical use of automated vehicles are underway. In particular, attention is being focused on a technology called “convoy driving,” in which multiple trucks communicate in real time about their driving conditions and automatically maintain a safe distance between them. A number of companies in Japan have already succeeded in demonstrating this technology on public roads, and it seems that it will soon be put to practical use.

- Demand Forecast – In order to improve the efficiency of deliveries, systems that predict future demand and sales volume based on past sales results and market trends are being used. By forecasting demand and sales, it is possible to determine the minimum amount of inventory needed at each location, which is effective in minimizing delivery losses and shortages. In recent years, services have also begun to emerge that use satellite imagery data to analyze the number of customers visiting a store in a given trade area, as well as customer demographics and other factors to predict sales demand in retail stores.

The Last Mile (Corporate-Individual)

Issue:

- Absentee Redelivery of Parcels and Cargo – According to a survey by the Ministry of Land, Infrastructure, Transport and Tourism, about 15% of all parcel deliveries are redeliveries. It is also estimated that 25% of driving distance is spent for redelivery, which is equivalent to 90,000 manhours of labor per year, which means about 180 million hours are spent on missed deliveries in a year. Although improvements have been made through the use of delivery boxes and the encouragement of time-of-day delivery, there is an urgent need to reduce the number of redeliveries and improve efficiency, as the EC market is expected to continue to expand amid a shortage of human resources.

Solution Through Technology:

- Drone Delivery – One of the solutions to the shortage of truck drivers and traffic congestion is the use of drones to conduct home deliveries. Although it has not yet been put to practical use, companies like Amazon and Rakuten are conducting demonstration experiments. There are still hurdles to overcome in terms of safety, technology, and legal regulations, but the results of these experiments are promising, such as Rakuten’s 2019 verification experiment in Chichibu City, Saitama Prefecture, wherein drones for deliveries were flown beyond visual range, with the cooperation of Tokyo Electric Power Holdings, Inc. and Zenrin.

So far, we have discussed the challenges of the logistics industry in recent years and the growing potential for the use of technology within the industry. The logistics crisis has had a major impact on manufacturers as well, and it is important to view issues in the logistics network as a management priority, rather than leaving these issues to logistics subsidiaries or contractors. In addition to considering the introduction of technology, it will be effective to develop a logistics system that is optimal for the sales channel structure, such as reviewing procurement and inventory management, and relocating logistics bases in preparation for demand fluctuations.